Comprehensive Operation Guide for Fully Automatic Multi-Functional Oil Press Machines to Boost Efficiency in Small and Medium Oil Enterprises

2025-11-08

Application Tutorial

Discover the efficient operation process and essential maintenance tips of fully automatic multi-functional oil press machines designed specifically for small and medium oil production enterprises. This tutorial guides you step-by-step from pre-start inspections, parameter settings, pressing and filtering monitoring, to routine maintenance checkpoints. Whether you are a new operator or a production supervisor, you’ll find practical solutions to reduce downtime, enhance oil yield, and improve oil quality. Learn how standardized operations can extend machine lifespan, stabilize output, and increase customer satisfaction.

Step-by-Step Guide to Operating Your Fully Automatic Multi-Functional Oil Press

Whether you’re a greenhorn operator or a seasoned production manager, mastering the operation of your fully automatic multi-functional oil press is key to maximizing efficiency, improving oil yield, and maintaining stable production. This detailed guide walks you through every essential phase—from pre-startup checks through pressing and filtering, to maintenance routines—helping your small-to-midsize oil refinery thrive in a competitive market.

1. Pre-Startup Inspection and Parameter Setup

Before powering on, perform a quick yet thorough inspection to avoid unexpected downtime. Check for:

- Proper installation and secure fittings of the pressing chamber and filtration components

- Absence of oil residue or foreign objects inside the crusher and screw

- Lubrication levels in critical joints and bearings

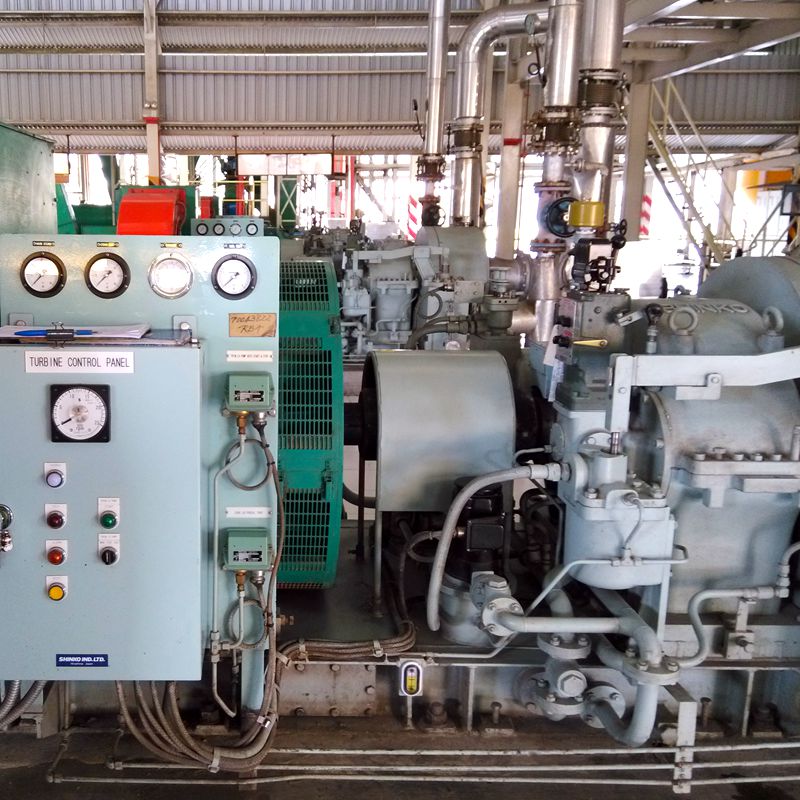

- Electrical connections and control panel integrity

Once verified, configure the press parameters according to your oilseed type. Typical settings to customize include:

| Parameter |

Typical Range |

Adjustment Tips |

| Pressing Temperature |

70–90°C |

Higher temps for oily seeds; avoid overheating |

| Pressing Speed |

15–25 rpm |

Slower speeds boost oil yield but reduce throughput |

| Screw Pressure |

Measured via control panel |

Maintain stable pressure to minimize oil & cake quality fluctuations |

2. Controlling the Pressing and Filtration Process

During operation, continuous monitoring is crucial. Focus on:

- Feedstock Flow: Maintain a steady and uniform feeding rate to avoid overloading.

- Temperature Stability: Fluctuations can compromise both yield and oil quality.

- Filtration Monitoring: Clean filters regularly to prevent clogging, which can cause pressure buildup and machine stoppage.

To optimize oil clarity and reduce impurities, regularly check the filtering system’s mesh size and replace worn parts timely.

3. Essential Maintenance Practices to Maximize Equipment Lifespan

Effective maintenance safeguards your investment and prevents costly downtime. Adopt the following:

| Maintenance Task |

Frequency |

Notes |

| Cleaning Press Chamber & Filters |

Daily |

Prevents residue buildup affecting pressing accuracy |

| Lubricating Moving Parts |

Weekly |

Reduces friction and wear, extending service life |

| Replacing Worn Screws & Dies |

Every 3–6 months depending on usage |

Avoids drop in pressing efficiency and oil quality deterioration |

| Energy Consumption Monitoring |

Monthly |

Identify anomalies early to prevent unexpected breakdowns |

4. Troubleshooting Common Operational Challenges

Small oil enterprises often face typical challenges that, if left unchecked, can severely impact production:

- Machine Stoppage: Usually caused by filter clogging or material jam. Solution: Pause and clean filtering system; verify seed moisture content (~7–9%) is within recommended limits.

- Low Oil Yield: May result from incorrect temperature or pressing speed. Adjust parameters to recommended values and confirm equipment is free from wear.

- Excessive Energy Usage: Inspect for worn bearings or motor overload; schedule timely lubrication and parts replacement to restore efficiency.

5. How You Benefit from Standardized Operation and Maintenance

By adhering to a consistent operation and maintenance routine, your oil press can deliver:

- Extended Equipment Lifespan: Proper care can increase machine longevity by over 30%.

- Stable and Higher Oil Yield: Consistent parameter control raises output by up to 15% compared to irregular operation.

- Improved Oil Quality: Minimizes impurities and oxidation risks thanks to timely filtration and temperature regulation.

- Reduced Downtime: Prevents unexpected breakdowns, supporting uninterrupted delivery to your customers.

Ready to unlock your oil press’s full potential? Click here to get your exclusive operating manual and start optimizing your oil extraction efficiency today!