Fully automatic peanut oil presses have become the preferred choice for many peanut oil production enterprises due to their high efficiency, energy - saving, and automation features. These presses can significantly reduce labor costs and improve production efficiency. For example, a traditional manual peanut oil production line may require 5 - 8 workers per shift, while a fully automatic peanut oil press can achieve the same production volume with only 1 - 2 workers, saving about 75% of labor costs.

The scope of application of these presses is quite wide, suitable for both small - scale peanut oil processing workshops and medium - to large - scale peanut oil production enterprises. Whether it is for local market supply or large - scale export, fully automatic peanut oil presses can meet different production needs.

When it comes to equipment selection, it is crucial to consider production capacity requirements. For small - scale peanut oil production lines with a daily output of less than 1 ton, a small - sized fully automatic peanut oil press with a power of about 5 - 10 kW is usually sufficient. For medium - scale production lines with a daily output of 1 - 5 tons, a press with a power of 10 - 20 kW is recommended. For large - scale production lines with a daily output of more than 5 tons, high - power presses of 20 kW or more are needed.

Here is a comparison table of equipment configurations for different production capacities:

| Production Capacity | Power of Press | Recommended Model |

|---|---|---|

| Less than 1 ton/day | 5 - 10 kW | Model A |

| 1 - 5 tons/day | 10 - 20 kW | Model B |

| More than 5 tons/day | 20+ kW | Model C |

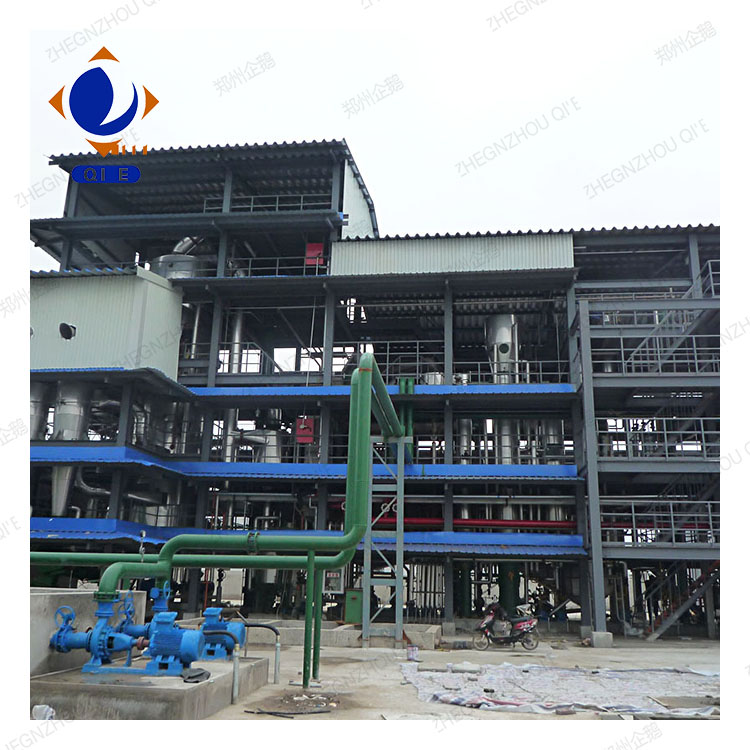

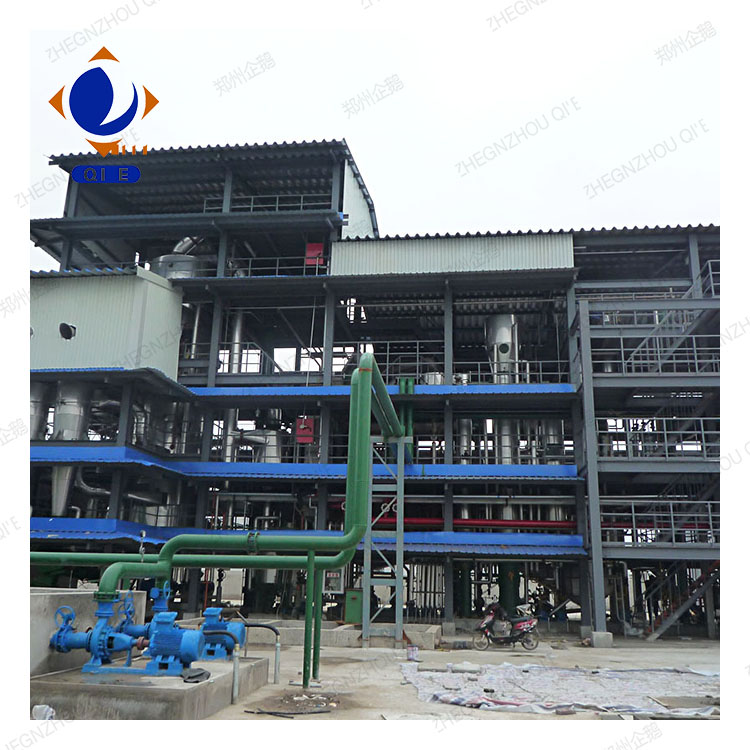

Before installing the fully automatic peanut oil press, proper site preparation is essential. The installation site should be flat and have sufficient space. The ground bearing capacity should be at least 1.5 - 2 tons per square meter to ensure the stable operation of the press. In addition, the site should have good ventilation and lighting conditions to prevent overheating of the equipment and ensure the safety of operators.

It is also necessary to ensure that the power supply meets the requirements of the equipment. The voltage fluctuation should be within ± 5% of the rated voltage, and the frequency should be stable at 50 Hz.

During the installation process, there are some common mistakes that need to be avoided. For example, improper alignment of the press components can lead to uneven stress and reduce the service life of the equipment. To avoid this, it is necessary to use professional measuring tools to ensure accurate alignment.

Another common mistake is the improper connection of pipelines. Loose or incorrect pipeline connections can cause oil leakage and affect the normal operation of the press. Therefore, it is necessary to carefully check the pipeline connections and use high - quality sealing materials.

The startup and debugging of the fully automatic peanut oil press is a crucial step to ensure its normal operation. First, conduct a comprehensive inspection of the equipment to ensure that all components are installed correctly and there are no loose parts. Then, fill the lubrication points with the appropriate lubricating oil.

Next, perform a no - load test run. Start the equipment at a low speed and observe the operation status of the press. Check for abnormal noises, vibrations, and temperature rises. If any problems are found, stop the equipment immediately and troubleshoot.

After the no - load test run is successful, conduct a load test run. Gradually increase the input of peanuts and adjust the operating parameters of the press according to the actual production situation. Monitor the oil output rate, oil quality, and other indicators to ensure that the equipment meets the production requirements.

During the operation of the fully automatic peanut oil press, some common problems may occur, such as low oil output rate, poor oil quality, and equipment failure. For low oil output rate, it may be caused by improper adjustment of the press parameters or poor quality of peanuts. Check and adjust the press parameters, and select high - quality peanuts.

For poor oil quality, it may be due to improper filtration or over - heating during the pressing process. Improve the filtration system and control the pressing temperature.

Regular maintenance is also essential to ensure the long - term stable operation of the equipment. Clean the equipment regularly, replace worn - out parts in time, and lubricate the moving parts.

Let's take a small - scale peanut oil processing workshop as an example. This workshop originally used a traditional manual peanut oil production line, with low production efficiency and high labor costs. After installing our fully automatic peanut oil press, the daily output increased from 0.5 tons to 1.2 tons, and the labor cost was reduced by 70%.

The workshop owner said that the installation process was smooth, and with the help of our professional technicians, they quickly mastered the operation and maintenance skills of the equipment. Now, the workshop has achieved stable and continuous production, and the economic benefits have been significantly improved.

To help users complete the production launch quickly and efficiently, here are some practical tips: 1. Follow the installation and operation manual strictly. 2. Keep in touch with our after - sales service team for timely technical support. 3. Train the operators in advance to ensure they are familiar with the equipment.

Our fully automatic peanut oil presses are designed with energy - saving, automation control, and high - efficiency features, which can bring you a more professional and profitable peanut oil production experience. Are you ready to upgrade your peanut oil production line?

Click here to learn more about our fully automatic peanut oil presses!

Do you have any questions about the installation and operation of fully automatic peanut oil presses? Leave your comments below and share your thoughts!