Are you still troubled by the high energy consumption and low efficiency of traditional peanut oil pressing processes? In this article, we'll take you on a deep - dive into the core technologies of fully automatic peanut oil presses, from the optimization of screw oil press structures to the application of PLC automatic control systems. We'll reveal how energy - saving and consumption - reduction can be achieved through mechanical design upgrades and intelligent control.

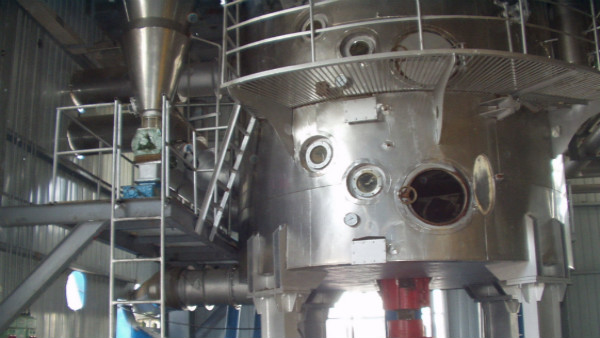

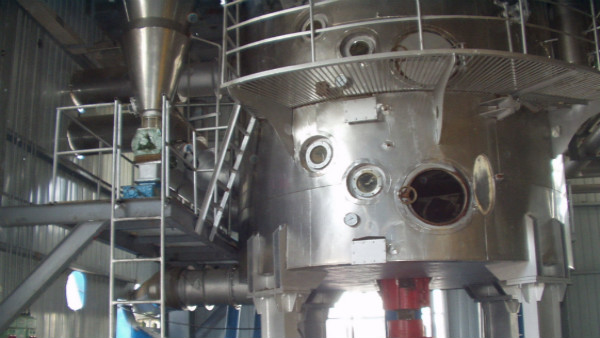

Let's start with the screw oil press structure optimization. The traditional screw oil press may have some structural limitations that affect the pressing efficiency. By optimizing the spiral angle, pitch, and diameter of the screw shaft, the pressing process becomes more efficient. The material moves more smoothly inside the press, which significantly improves the pressing efficiency.

The PLC automatic control system is another key factor. It can precisely control the speed of the screw shaft, the temperature inside the press, and the pressure during the pressing process. This intelligent control not only ensures the stability of the pressing process but also reduces unnecessary energy consumption. For example, it can adjust the speed according to the material feeding rate, avoiding over - operation and thus saving energy.

In actual production, there are often some common problems. Low oil yield is a headache for many users. This may be due to improper screw shaft design or inaccurate pressure control. By upgrading the screw shaft and using the PLC system to adjust the pressure in real - time, the oil yield can be effectively improved. In some cases, the oil yield can be increased by 8 - 10%.

High energy consumption is another major issue. Traditional presses may run at a constant high - power mode, resulting in waste. With the new technology, the power can be adjusted according to the actual processing volume. On average, the unit energy consumption can be reduced by 15%.

Blockage is also a common problem. It may be caused by the accumulation of peanut residues. Through structural optimization, such as adding anti - blockage devices and using the PLC system to monitor the material flow, blockages can be effectively prevented.

Different peanut varieties have different physical properties. For example, some peanuts have a higher oil content, while others have a harder shell. By adjusting the parameters of the press, such as the pressing speed, temperature, and pressure, the press can better adapt to different peanut varieties, thereby improving the overall production capacity.

Temperature control also has a significant impact on the flavor of the oil. By precisely adjusting the temperature during the pressing process, the flavor of the peanut oil can be enhanced. For example, a slightly higher temperature can bring out a richer nutty flavor, but too high a temperature may damage the nutritional components. By mastering 3 parameter - setting skills, you can easily achieve both high - quality oil production and energy - saving goals.

To help you better understand the differences between traditional and automated processes, we suggest inserting a comparison flowchart. You can also use energy consumption data tables to show the obvious advantages of the new technology. Operation key - point reminder boxes can be used to help operators quickly master the operation skills.

This technology has great value in the industry. Whether you are a small - to - medium - sized farm or a large - scale processing enterprise, it can bring you significant benefits. It supports sustainable production goals, reduces energy consumption, and improves production efficiency.

Are you ready to transform your peanut oil production line into a more efficient and environmentally - friendly one? With our new technology, you can easily achieve this goal. Click here to learn more about our energy - saving peanut oil pressing solutions and start your journey towards a more profitable and sustainable production!