In the competitive landscape of small and medium-sized oil enterprises, choosing the right oil press machine plays a critical role in boosting production efficiency, optimizing operational costs, and ensuring sustainable business growth. Exploring six key dimensions—pressing efficiency, energy consumption, user-friendliness, versatility in oilseed compatibility, multifunction integration, and material durability—reveals how manufacturers can balance cost and performance when selecting equipment.

Pressing efficiency directly impacts output volume and profitability. Advanced technologies in modern oil press machines have demonstrated oil yield improvements of up to 12–15% compared to traditional methods. For example, machines utilizing optimized screw press designs and adjustable pressure settings can consistently achieve extraction rates exceeding 95% on common oilseeds such as sunflower, peanut, and rapeseed.

Energy efficiency is paramount for operational cost reduction and environmental compliance. High-efficiency oil presses often consume 20–30% less energy than older models by integrating variable frequency drives (VFD) and intelligent control systems. These innovations enable machines to optimize motor speed and pressure dynamically based on oilseed types, reducing unnecessary power usage without compromising yield.

Minimizing operational complexity reduces training time and labor costs. Fully automated oil press machines with touchscreen interfaces, real-time monitoring, and fail-safe mechanisms enhance operator convenience. Equipment with modular components also accelerates maintenance procedures, limiting downtime to less than 4 hours per month on average, thus maintaining steady production.

| Dimension | Traditional Machines | Modern Automatic Presses |

|---|---|---|

| Pressing Efficiency | 80-85% | 95-98% |

| Energy Consumption (kWh/ton) | 120-150 | 80-100 |

| Maintenance Downtime per Month | 10+ hours | <4 hours |

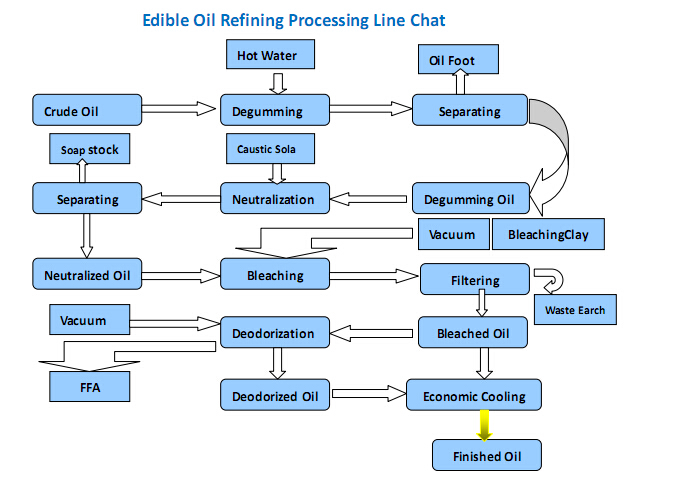

Versatile machines expand processing capabilities across various seeds and nuts, including soybean, sesame, palm kernel, and flaxseed. Multi-functional models integrate pressing, filtering, and cake discharging capabilities into one seamless workflow, streamlining production and cutting additional equipment investment by nearly 25%.

High-grade stainless steel and corrosion-resistant alloys form the backbone of durable oil press machines. Quality materials not only extend machine life beyond 10 years but also ensure food-grade safety standards, reducing contamination risks. Selecting equipment with warranties covering core components for at least 3 years minimizes unforeseen expenses.

Leading-edge oil presses now feature IoT-enabled monitoring and AI-assisted process controls that continuously optimize operational parameters. While the upfront cost may be 15–20% higher, the total cost of ownership drops significantly due to energy savings, reduced labor, and higher output quality.

Real-world user case studies reveal that integrating such equipment facilitated a 25% capacity increase within 6 months, while power consumption declined by roughly 22%. These figures emphasize the tangible ROI achievable for small and medium oil enterprises prioritizing smart machine investment.

Purchasing decisions are best grounded in a supplier’s service profile. Reliable support in installation, training, spare parts sourcing, and troubleshooting ensures minimal disruption and maximum lifecycle value.