In the food processing industry, the demand for high-quality edible oils combines stringent safety requirements with the need for energy efficiency and operational reliability. Having worked extensively with peanut oil production enterprises worldwide, it has become evident that energy consumption and product consistency remain critical challenges for many manufacturers. This article delves into how low-energy peanut oil pressing machines meet these challenges, integrating intelligent control systems and internationally recognized quality standards to drive modern food processing towards safer and more sustainable production.

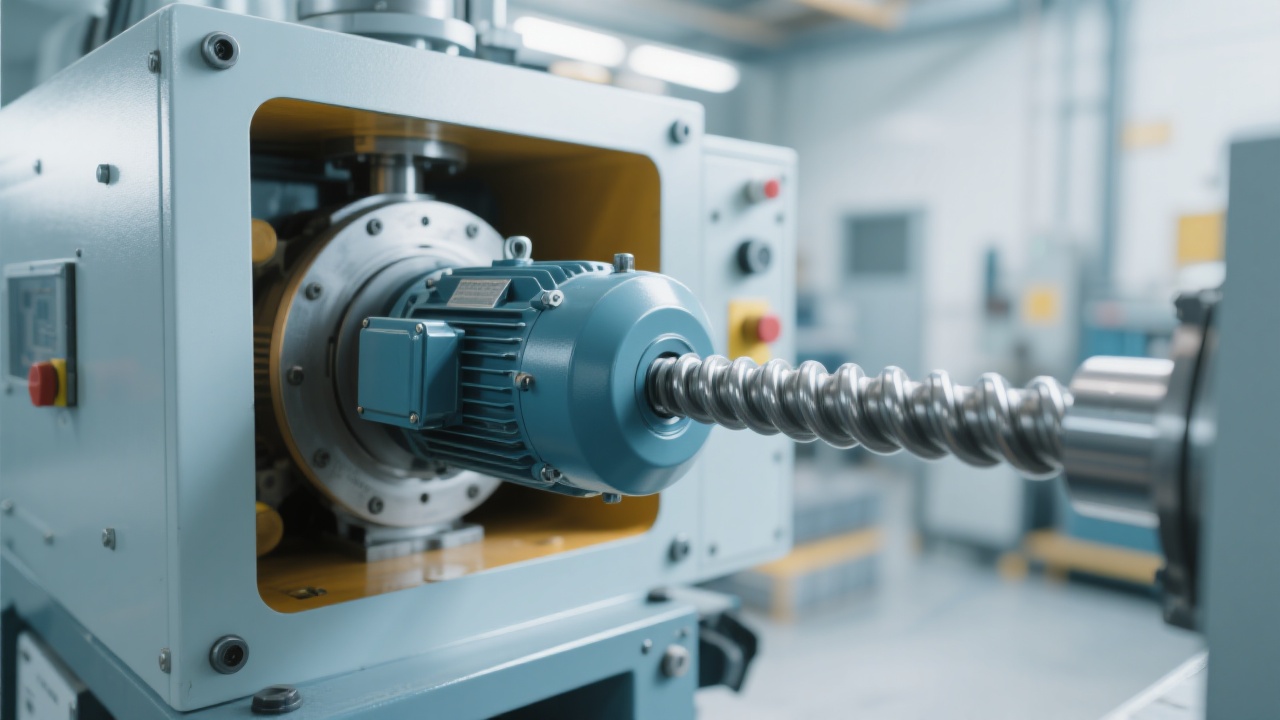

The backbone of an efficient peanut oil production line is equipment optimized for low power consumption without compromising output. Modern pressing machines utilize high-torque motors paired with advanced mechanical designs that reduce friction and thermal losses, achieving energy savings of up to 25% compared to conventional models. Coupled with a compact footprint and user-friendly interfaces, these machines adapt seamlessly to both traditional oil mills and automated food processing facilities.

Moreover, the pressing units are engineered to maintain mechanical and operational stability under varying loads, directly translating to consistent oil yield and enhanced product quality. This is critical as fluctuations can lead to batch-to-batch variability, a common pain point in oil production that results in quality disputes and financial loss.

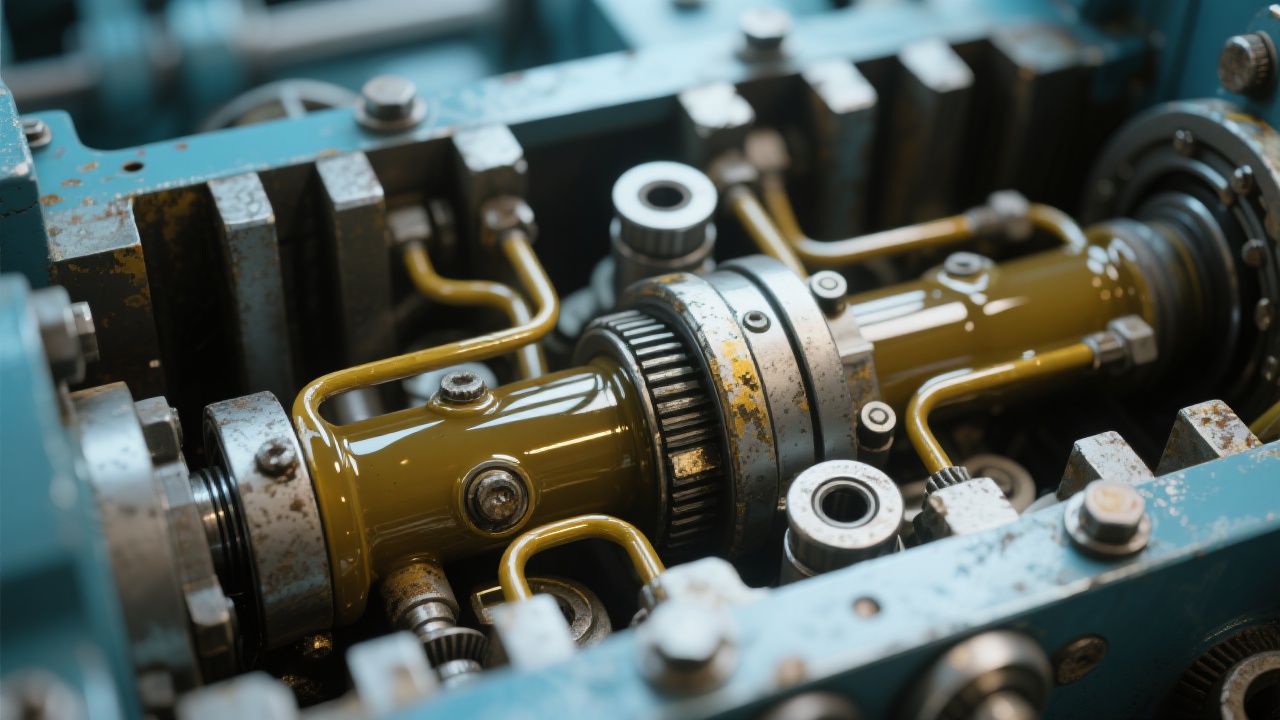

The integration of intelligent control systems marks a paradigm shift in oil pressing technologies. These systems continuously monitor parameters such as temperature, pressure, and extraction speed, automatically adjusting operations to optimize output quality while minimizing energy use. For instance, a feedback loop may reduce motor speed upon detecting excess heat, thus preventing nutrient degradation in the peanut oil.

In practice, some leading food processors report a 10% increase in refined oil purity and a 15% reduction in power consumption after adopting intelligent controls. Additionally, such systems support predictive maintenance by analyzing operational data trends, reducing unexpected downtime by up to 30%.

Whether in a traditional family-owned oil mill or a fully automated large-scale food processing plant, the equipment’s adaptability is paramount. Low-energy peanut oil pressing machines demonstrate robust performance across environments with varying humidity, temperature, and raw material quality. Their modular design allows easy customization — from input capacity scaling to integration with downstream refining units — making them suitable for multiple production scenarios.

For example, a Southeast Asian peanut oil manufacturer successfully transitioned from outdated hydraulic presses to this modern technology, resulting in a 20% increase in daily output while reducing energy expenses by nearly 18%. The equipment’s reliability also minimized maintenance times, a critical indicator in high-throughput operations.

One of the key differentiators of these pressing machines is their compliance with the ISO9001:2000 standard, reflecting a commitment to comprehensive quality and safety management systems. This certification underscores rigorous controls across design, manufacturing, and testing processes — assuring customers of consistent product safety, traceability, and regulatory compliance.

For food processors, this translates to enhanced brand confidence, simplified audit procedures, and alignment with international food safety requirements, thereby easing export approvals and opening new markets.

Robust equipment is only part of the equation. A specialized support team is indispensable in helping clients navigate installation, commissioning, training, and ongoing maintenance. Many food processing companies emphasize the value of prompt responsive service that reduces operational hiccups.

Companies partnering with suppliers offering 24/7 technical assistance and tailored maintenance contracts report up to 40% fewer emergency repairs. These services also extend equipment life and uphold performance, ultimately maximizing clients' return on investment.

With global demand for healthier and sustainably produced edible oils rising, manufacturers are increasingly prioritizing equipment that minimizes environmental impact while ensuring product excellence. Innovations like predictive analytics, IoT-enabled monitoring, and eco-friendly materials are gaining traction, pushing the boundaries of what the next-generation peanut oil production lines will look like.

This technology evolution aligns with stricter food safety policies, carbon footprint reduction goals, and consumer expectations for traceability — positioning low-energy, ISO-certified oil pressing equipment as a future-proof investment.

Choosing a peanut oil pressing machine that balances low energy consumption, quality assurance, and operational reliability is essential to remain competitive in today’s food industry landscape. The integration of intelligent control systems and adherence to ISO9001:2000 standards represent key enablers for sustained production excellence.

Additionally, partnering with a supplier offering comprehensive technical support ensures smooth project implementation and long-term cost efficiency. Manufacturers aiming to upgrade or establish new production lines should prioritize these criteria to maximize their investments’ value and sustainability.

| Feature | Benefit | Impact |

|---|---|---|

| Low Energy Consumption | Reduced operational costs | Up to 25% energy savings |

| Intelligent Control System | Ensures product consistency & predictive maintenance | 10% oil purity improvement, 30% less downtime |

| ISO9001:2000 Certification | Quality and safety assurance | Streamlined compliance & market expansion |

| Professional Technical Support | Minimized downtime & extended equipment life | 40% fewer emergency repairs |

In your experience within the peanut oil or edible oil industry, have you faced challenges related to energy efficiency or product quality? What solutions have you found effective? Share your insights or questions below — our expert team is ready to provide tailored examples from peers to support your production goals.