In the realm of peanut oil production, energy - saving and consumption - reduction have emerged as a prominent industry trend. With the increasing emphasis on environmental protection and cost - effectiveness, manufacturers are constantly seeking ways to improve the efficiency of peanut oil presses. Traditional peanut oil production methods often consume large amounts of energy, which not only increases production costs but also goes against the global trend of green development. Therefore, the development of low - energy peanut oil presses has become an inevitable choice for the industry.

The safety and reliability of equipment are also crucial for peanut oil production. Any malfunction or safety issue in the production process can lead to production interruptions, product quality problems, and even endanger the safety of workers. As such, modern peanut oil presses need to be designed with high - level safety features to ensure smooth and stable production.

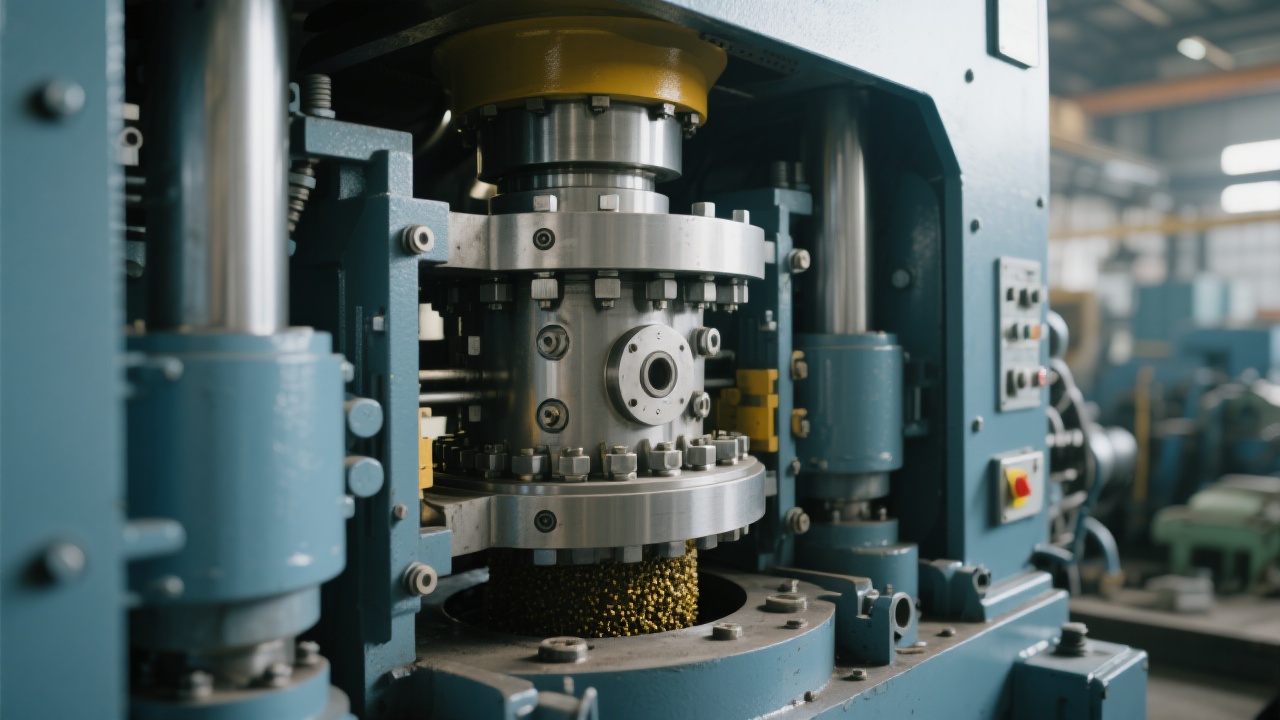

Low - energy peanut oil presses are equipped with intelligent control systems. These systems can automatically adjust various parameters during the pressing process, such as temperature, pressure, and speed. For example, they can optimize the pressing process according to the moisture content and quality of peanuts, ensuring high - quality oil extraction while minimizing energy consumption. This intelligent adjustment not only improves production efficiency but also reduces the need for manual operation, saving labor costs.

One of the remarkable features of these presses is their high oil yield, which ranges from 98% - 100%. This means that almost all the oil in peanuts can be extracted, maximizing the utilization of raw materials. Compared with traditional presses with an average oil yield of about 90% - 95%, the low - energy peanut oil presses can significantly increase the output of peanut oil with the same amount of raw materials.

Through advanced design and technology, low - energy peanut oil presses can reduce energy consumption by up to 30% compared with traditional models. For example, some presses use energy - efficient motors and optimized transmission systems to minimize power loss during operation. This not only reduces the overall energy consumption of the production line but also helps enterprises achieve cost savings in the long run.

These peanut oil presses comply with the ISO 9001:2000 standard, which is an internationally recognized quality management system. This certification ensures that the products meet strict quality and safety requirements during the design, production, and after - sales service processes. It also enhances the credibility and competitiveness of the products in the international market.

In traditional oil processing factories, where the production scale is often large and the equipment may be relatively old, low - energy peanut oil presses can be easily integrated into the existing production lines. Their high efficiency and energy - saving features can help these factories upgrade their production technology, improve product quality, and reduce production costs. For example, a traditional oil factory in [Location] replaced its old peanut oil presses with low - energy models. After the replacement, the energy consumption of the peanut oil production line decreased by 25%, and the oil yield increased by 3%.

In modern food production lines, which require high - precision and high - quality production processes, low - energy peanut oil presses can meet the strict requirements for product quality and production efficiency. Their intelligent control systems can be connected to the overall production management system, enabling real - time monitoring and adjustment of the production process. For instance, a modern food company in [Location] uses low - energy peanut oil presses in its peanut - based food production line. The stable oil quality and high - efficiency production provided by these presses have contributed to the company's continuous improvement in product quality and market competitiveness.

Let's take a look at some real - world customer cases. A medium - sized peanut oil processing enterprise in Africa purchased several low - energy peanut oil presses. Before the purchase, the enterprise was facing high energy costs and relatively low oil yields. After using the new presses, the energy cost per ton of peanut oil production decreased by 30%, and the oil yield increased from 95% to 98%. The enterprise was also satisfied with the after - sales technical support provided by the manufacturer, which ensured the smooth operation of the equipment.

The peanut oil press industry is constantly evolving. New technologies such as artificial intelligence, big data, and the Internet of Things are gradually being applied to peanut oil production. These technologies can further optimize the production process, improve product quality, and enhance the overall competitiveness of enterprises. For example, through big data analysis, manufacturers can better understand the market demand and product performance, and then make more targeted improvements to the equipment.

Do you have any questions about low - energy peanut oil presses? Or are you interested in learning more about how these devices can transform your peanut oil production? Feel free to leave a message below or contact us for more information. We're here to help you enhance production efficiency, ensure product quality, and choose intelligent energy - saving equipment for a green future.