Are you in the market for an efficient and reliable peanut oil press machine? Look no further! Our export-oriented fully automatic peanut oil press machine offers a range of core advantages, including high production capacity, low maintenance requirements, and compatibility with multiple varieties of raw materials. In this article, we'll delve into the key technologies that make this machine a game-changer in the peanut oil extraction industry.

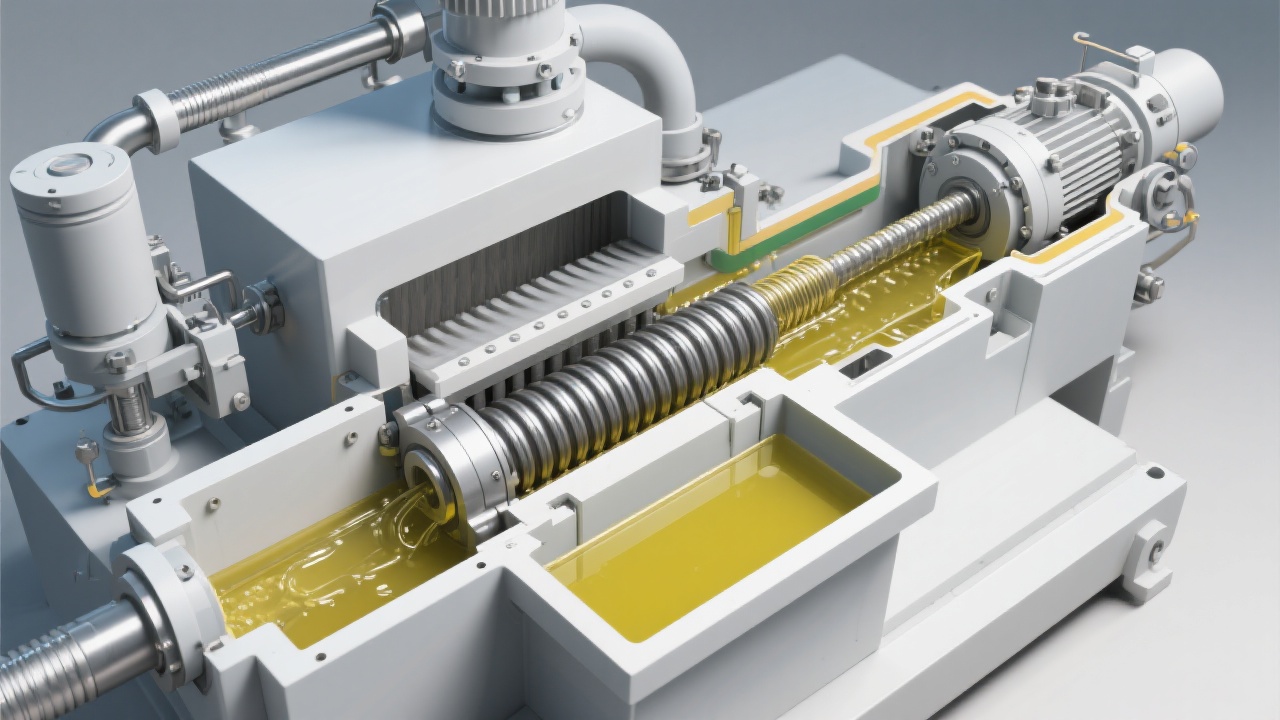

The mechanical structure of our peanut oil press machine has been carefully designed and optimized. We adopt the double-stage pressing principle, which significantly improves the pressing efficiency. By applying wear-resistant materials, the durability of the machine is greatly enhanced, reducing the frequency of part replacements and maintenance costs. For example, the wear-resistant alloy used in the screw shaft can withstand high pressure and friction, ensuring long - term stable operation.

The PLC automatic control system is the heart of our fully automatic peanut oil press machine. It enables the machine to operate unattended. The PLC program precisely controls every step of the pressing process, from feeding to oil extraction. With the help of sensors and actuators, the machine can adjust the pressing parameters in real - time according to the material conditions. For instance, it can automatically adjust the pressing speed and pressure to ensure the best oil extraction effect, whether you are processing a small batch or a large - scale production.

We understand the importance of energy efficiency in modern production. Our peanut oil press machine is equipped with advanced energy - saving technologies. The temperature control system ensures that the pressing process is carried out at the optimal temperature, reducing unnecessary energy consumption. The motor frequency conversion adjustment technology allows the motor to operate at the most appropriate speed according to the actual load, which can reduce the unit energy consumption by up to 15%. By implementing these strategies, you can save a significant amount of energy costs in the long run.

In addition to high efficiency and energy - saving, our peanut oil press machine also pays attention to environmental protection. We have adopted measures for waste residue recycling and utilization. The peanut residues can be used as animal feed or fertilizer, realizing the full utilization of resources. At the same time, the dust control measures effectively reduce the dust emission during the production process, creating a clean and healthy working environment.

Different peanut varieties have different physical and chemical properties. Our peanut oil press machine can be adjusted to adapt to various peanut varieties. Through real - world case studies, we have developed specific adjustment methods for different peanut varieties. By adjusting the pressing parameters such as pressure, speed, and temperature, we can ensure that the oil extraction rate is maximized and the quality of the peanut oil meets international standards.

We know that some common problems may occur during the operation of peanut oil press machines, such as low oil extraction rate, blockage faults, and flavor deterioration caused by heat damage. Our technical team has conducted in - depth analysis of these problems and provided corresponding solutions. For example, by optimizing the screw structure and adjusting the feeding speed, we can effectively solve the blockage problem. By controlling the temperature and pressing time, we can avoid heat damage to the peanut oil and maintain its original flavor.

Whether you are a small - scale farmer or a large - scale oil processing enterprise, by mastering these key technologies, you can increase the oil extraction rate by more than 15%, reduce the unit energy consumption, and ensure that the quality of your peanut oil meets international standards stably. Don't miss this opportunity to upgrade your peanut oil production. Click here to learn more about our high - performance peanut oil press machine!