In the realm of edible oil production, optimizing peanut oil yield is a cornerstone challenge for manufacturers. Having worked extensively with clients across Asia and Africa, technical consultants often observe that the bottleneck lies not merely in raw material quality but in the nuanced engineering of the pressing equipment—especially the spiral oil press mechanism.

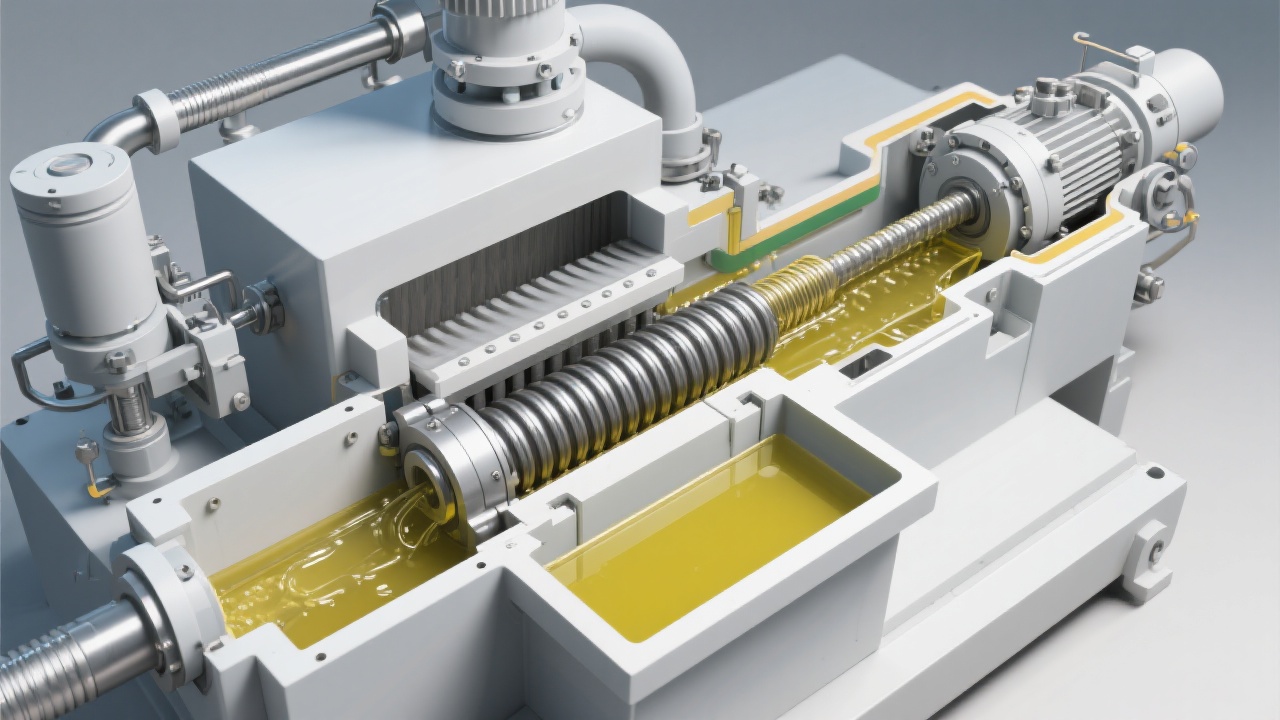

The spiral oil press is quintessential in automatic peanut oil extraction due to its continuous operation and consistent screw conveyor design. However, not all spiral presses are created equal. The heart of performance improvements lies in dissecting and refining the mechanical structure, which directly impacts throughput and extraction efficiency.

The spiral press comprises a tightly engineered screw shaft, combined with a tailored sleeve and differential speed zones. Recent advances demonstrate that by adopting a segmented screw shaft design—where pitch, groove depth, and diameter vary purposefully along the shaft length—manufacturers can optimize the compression and shear forces exerted on peanut kernels.

For instance, an industry-leading design employs a gradual decrease in pitch from the feed end to the discharge outlet. This creates a compression gradient, effectively squeezing out more oil as the material advances. Moreover, integrating a taper ring section enhances the seal between the shaft and the sleeve, reducing oil backflow and minimizing kernel residue in the cake. These subtle but critical modifications have shown to increase oil extraction rates by up to 8-12%, based on comparative testing utilizing standardized peanut varieties.

However, these gains hinge on meticulous balancing—an overly aggressive compression risks excessive kernel pulverization, raising impurities and reducing oil quality. Thus, precision machining to tight tolerances (±0.02 mm) for the screw and sleeve components is essential to maintain optimal pressure without sacrificing throughput or oil clarity.

Modern fully automatic peanut oil presses integrate intelligent control systems that continuously monitor and adjust process parameters such as feeding rate, screw speed, and temperature. These feedback loops are pivotal in adapting to variations in peanut variety moisture, kernel hardness, and ambient temperature, which all significantly influence oil yield.

For example, a client in Southeast Asia faced yield inconsistencies due to seasonal moisture fluctuations. By implementing sensor-driven temperature control within the pressing chamber coupled with variable frequency drive (VFD) screw speed control, the system dynamically maintained an optimal pressing condition, improving yield stability by over 10%. This not only enhanced output but also reduced energy consumption by 15%, illustrating the intertwined benefits of automation and energy efficiency.

Beyond mechanical and automation improvements, the implementation of energy-saving components is becoming a critical competitive factor. Employing regenerative heat recovery systems recycles thermal energy from pressing chambers to preheat incoming peanuts, cutting down auxiliary heater loads by approximately 12%. Likewise, optimizing screw motor efficiency with premium-grade synchronous motors lowers electrical demand and avoids overheating risks.

Additionally, advances in ecological design include improved oil cake discharge mechanisms that reduce waste buildup and facilitate easier cleaning, thus minimizing residual oil oxidation that can lead to off-flavors and environmental pollution.

It’s often underappreciated how significantly peanut variety and processing temperature influence pressing outcomes. Varieties with higher protein and fiber content tend to yield less oil under identical mechanical conditions. Temperature control also plays a nuanced role; heating peanuts to approximately 60-70°C before pressing improves cell wall rupture but overheating beyond 80°C risks oil quality degradation due to thermal breakdown.

Case studies from West African operations reveal that fine-tuning screw speed and chamber temperature according to specific batch characteristics enabled a 5-7% rise in extractable oil yield without compromising flavor or shelf life. Such tuning requires not only equipment with flexible parameter settings but also operators trained in recognizing subtle raw material variations.

| Parameter | Conventional Press | Optimized Spiral Press |

|---|---|---|

| Average Oil Yield (%) | 38-42 | 45-50 |

| Energy Consumption (kWh/ton) | 85-90 | 70-75 |

| Pressing Time (min/ton) | 50-55 | 40-45 |

Clearly, these data point toward the tangible benefits of investing in mechanical and control system upgrades. Of course, the optimal choice depends on your factory’s scale, peanut source, and downstream refining capabilities.

Pro Tip: By fine-tuning the screw press’s key parameters, customers can achieve up to a 15% reduction in unit energy consumption, thereby markedly boosting ROI without compromising on oil quality. Continuous monitoring and adaptive control systems are essential to sustain these benefits.

The journey toward optimized peanut oil pressing doesn’t end here. Industry trends are shifting toward greater sustainability, digitalization, and smart maintenance—areas ripe for further innovation.

You’ve probably encountered similar challenges in your oil extraction processes. What specific issues affect your current pressing line’s output or energy efficiency? Feel free to share your context, and we can provide you with three tailored solutions from peers in your industry to spark inspiration and improvement.

Explore Proven Peanut Oil Pressing Solutions & Boost Your Yield Today