In the highly competitive global market of edible oil production, especially for export - processing enterprises, choosing the right equipment is crucial for cost - reduction and efficiency improvement. The energy - efficient and fully automatic peanut oil press is specifically designed to meet the needs of these enterprises. This article will comprehensively introduce the selection and installation of this equipment, providing a full - process guide for users.

When selecting a fully automatic peanut oil press, production scale and budget are two key factors. For small - scale export - processing enterprises with a daily production capacity of about 1 - 5 tons, a model with a relatively small capacity can be chosen. For example, the XYZ model can process 2 tons of peanuts per day, with an energy consumption of only 15 kWh per ton of peanuts, which is 20% lower than similar products in the market. This not only reduces energy costs but also meets the production needs of small - scale enterprises.

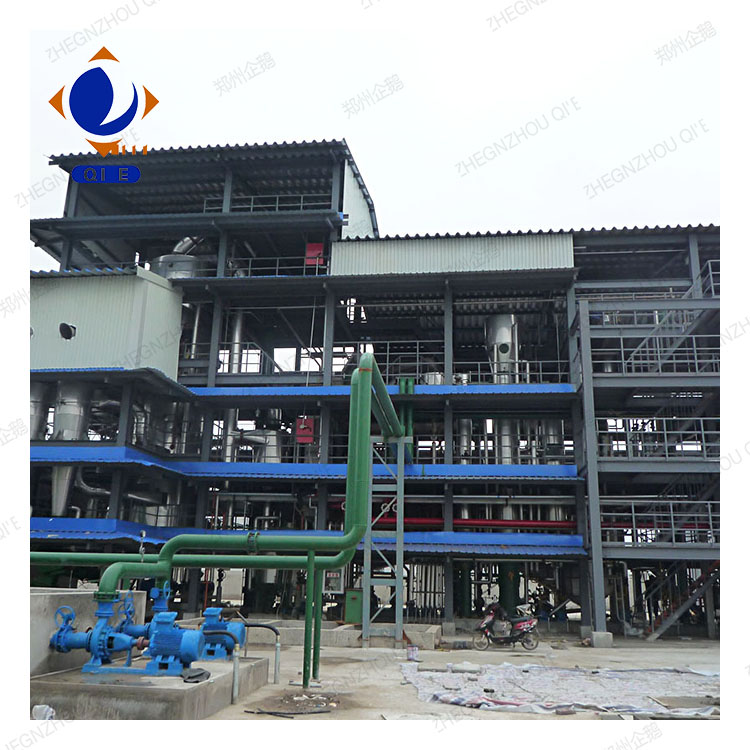

For medium - and large - scale enterprises with a daily production capacity of more than 5 tons, high - capacity models are more suitable. The ABC model can process 10 tons of peanuts per day. Its advanced automation control system can achieve continuous operation, increasing production efficiency by 30% compared with traditional presses. Although the initial investment is relatively high, in the long - run, it can significantly reduce labor costs and improve overall production efficiency.

Before installing the peanut oil press, proper site preparation is essential. The site should be flat, with a load - bearing capacity of at least 500 kg per square meter to ensure the stability of the equipment. The area of the site should be determined according to the size of the equipment and the operation requirements. For example, for a large - capacity press, an area of about 50 - 100 square meters is required to ensure smooth material handling and maintenance operations.

It is necessary to ensure that the power supply meets the requirements of the equipment. The rated voltage of the equipment should be 380V, and a dedicated power line should be used to avoid power interference. At the same time, the ventilation system of the site should be good to prevent the over - heating of the equipment during operation. For example, installing exhaust fans can effectively reduce the temperature in the workshop and ensure the normal operation of the equipment.

During the installation process, it is necessary to strictly follow the installation manual. One common mistake is the improper connection of pipelines. For example, if the oil outlet pipeline is not tightly connected, it may lead to oil leakage, which not only causes waste but also affects the working environment. To avoid this, it is necessary to use high - quality sealing materials and check the connection status regularly.

Another mistake is the incorrect installation of the control system. If the wiring is wrong, it may cause the equipment to malfunction or even damage. Therefore, it is recommended that professional technicians be invited for installation and debugging to ensure the correct installation of the control system.

After the installation is completed, a full - process commissioning is required. First, conduct a no - load test to check whether the operation of the equipment is normal, including the rotation of the motor, the movement of the conveyor belt, etc. Then, conduct a load test, gradually increasing the feed amount to check the oil extraction rate and energy consumption of the equipment. During the operation, if problems such as abnormal noise or vibration occur, it is necessary to stop the machine immediately for inspection.

In terms of maintenance, regular cleaning of the equipment is required to prevent the accumulation of oil residues and impurities. For example, cleaning the filter screen every week can ensure the smooth flow of oil. At the same time, lubricate the moving parts regularly to reduce wear and extend the service life of the equipment.

Let's take a medium - scale export - processing enterprise as an example. Before using the energy - efficient and fully automatic peanut oil press, its daily production capacity was 3 tons, with high energy consumption and low oil extraction rate. After replacing with the new equipment, its daily production capacity increased to 5 tons, the energy consumption per ton of peanuts decreased by 25%, and the oil extraction rate increased from 40% to 45%. This not only reduced production costs but also improved product quality, enabling the enterprise to gain a greater market share.

In conclusion, the energy - efficient and fully automatic peanut oil press is an ideal choice for export - processing enterprises. By choosing the right equipment, correctly installing and maintaining it, enterprises can achieve cost - reduction, efficiency improvement, and enhance their market competitiveness. Do you have any experience in installing peanut oil presses? Please share your thoughts in the comments section below. If you want to learn more about this energy - efficient and fully automatic peanut oil press, click here for more information.