For small and medium-sized edible oil producers, achieving consistent high yield isn’t just about raw material—it’s about how you press it. In fact, studies show that intelligent pressure control alone can boost soybean oil extraction by up to 12%, while proper temperature regulation reduces energy costs by 18% (Source: Journal of Food Engineering, 2023).

The journey from soybeans to golden oil involves precise steps:

“A well-calibrated pressing system doesn't just extract more oil—it preserves quality.” — Dr. Lin Mei, Senior Process Engineer at Sino-Oil Tech

| Oil Type | Baseline Yield (%) | Optimized Yield (%) | Improvement |

|---|---|---|---|

| Soybean Oil | 18.5% | 20.7% | +2.2 pts |

| Peanut Oil | 22.1% | 24.6% | +2.5 pts |

| Palm Oil | 42.3% | 45.1% | +2.8 pts |

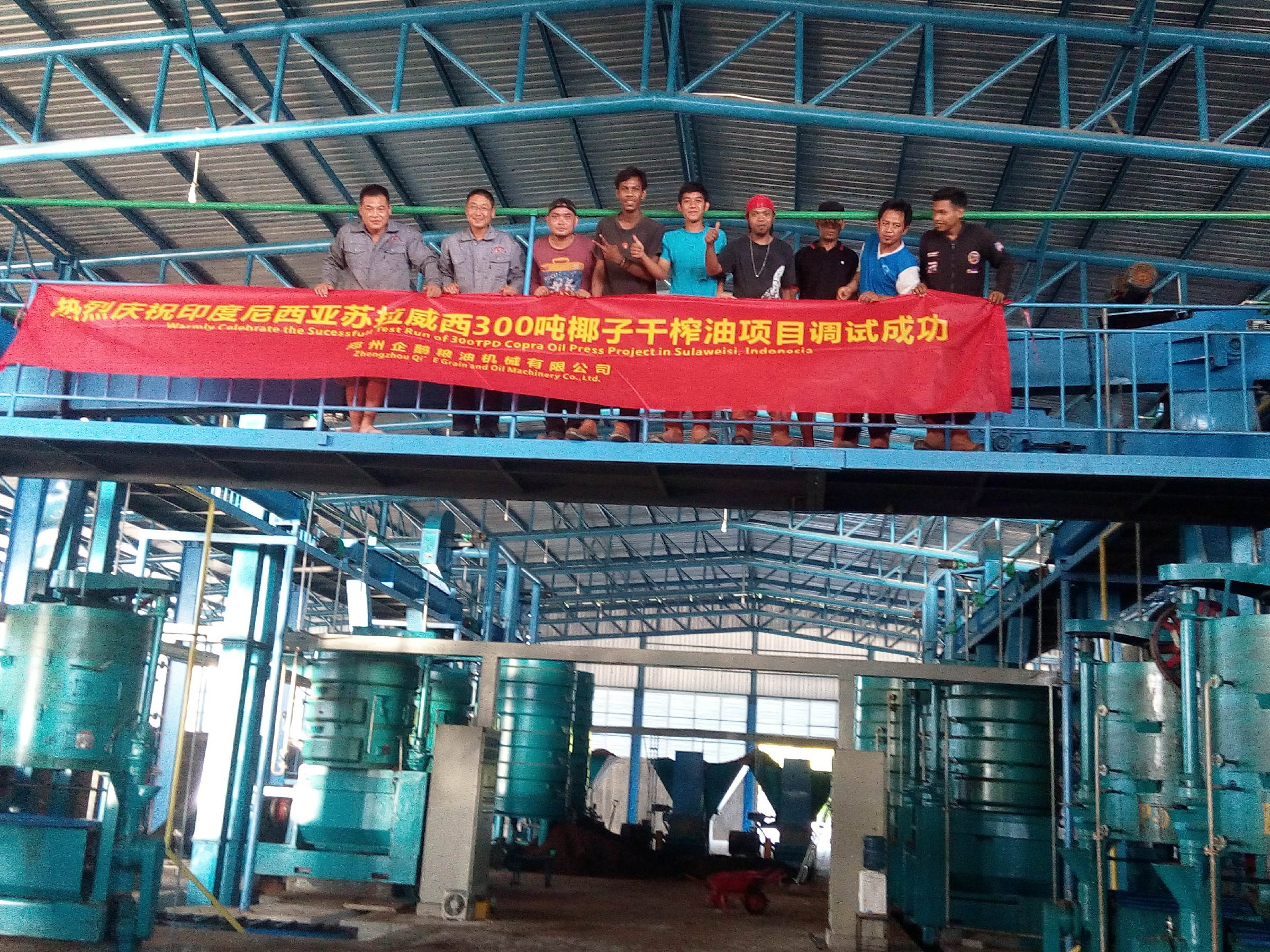

These improvements aren’t theoretical—they’re proven across hundreds of installations worldwide. One client in Nigeria reported a 15% increase in daily output after switching to our smart press + filtration combo.

But here’s the catch: many operators still rely on manual adjustments or outdated equipment. That means missed opportunities—and unnecessary waste.

Want to know if your current setup is holding back yields? Try this quick check:

❓ Have you noticed inconsistent oil output despite using the same raw materials?

If yes, you’re likely missing one or more key variables—pressure consistency, moisture control, or filter maintenance. These are all within reach with modern automation.

As global demand for sustainable, efficient food production grows, smart oil presses aren’t just an upgrade—they’re a necessity. They reduce labor intensity, lower failure rates, and help meet stricter international standards like ISO 22000 and HACCP.

See How Our Auto Press System Boosted Yields for 100+ Clients